Circdal Moves 3D Printing Industry Beyond Prototypes, Into Architecture

CONTACT · ANNABEL THORPE, CIRCDAL

PHONE · 214-543-8233

EMAIL · ANNABEL@CIRCDAL.COM

PRINTERIOR WEBSITE: printeriordesigns.com

Just need the text—no fluff? See below.

Circdal Launches To Move 3D Printing Industry Beyond Prototypes—and Into Architecture

ST. LOUIS, Missouri — For years, large-format 3D printing has been largely siloed to prototyping in specialized industries such as aerospace, automotive, and industrial manufacturing. While the technology itself has advanced rapidly, its application in the built environment, particularly in the United States, has remained limited—until now.

This week, Printerior, a powerhouse 3D printing and materials manufacturer, announced the launch of Circdal, a new Printerior company that expands the role of additive manufacturing into fully realized, completely circular architectural systems.

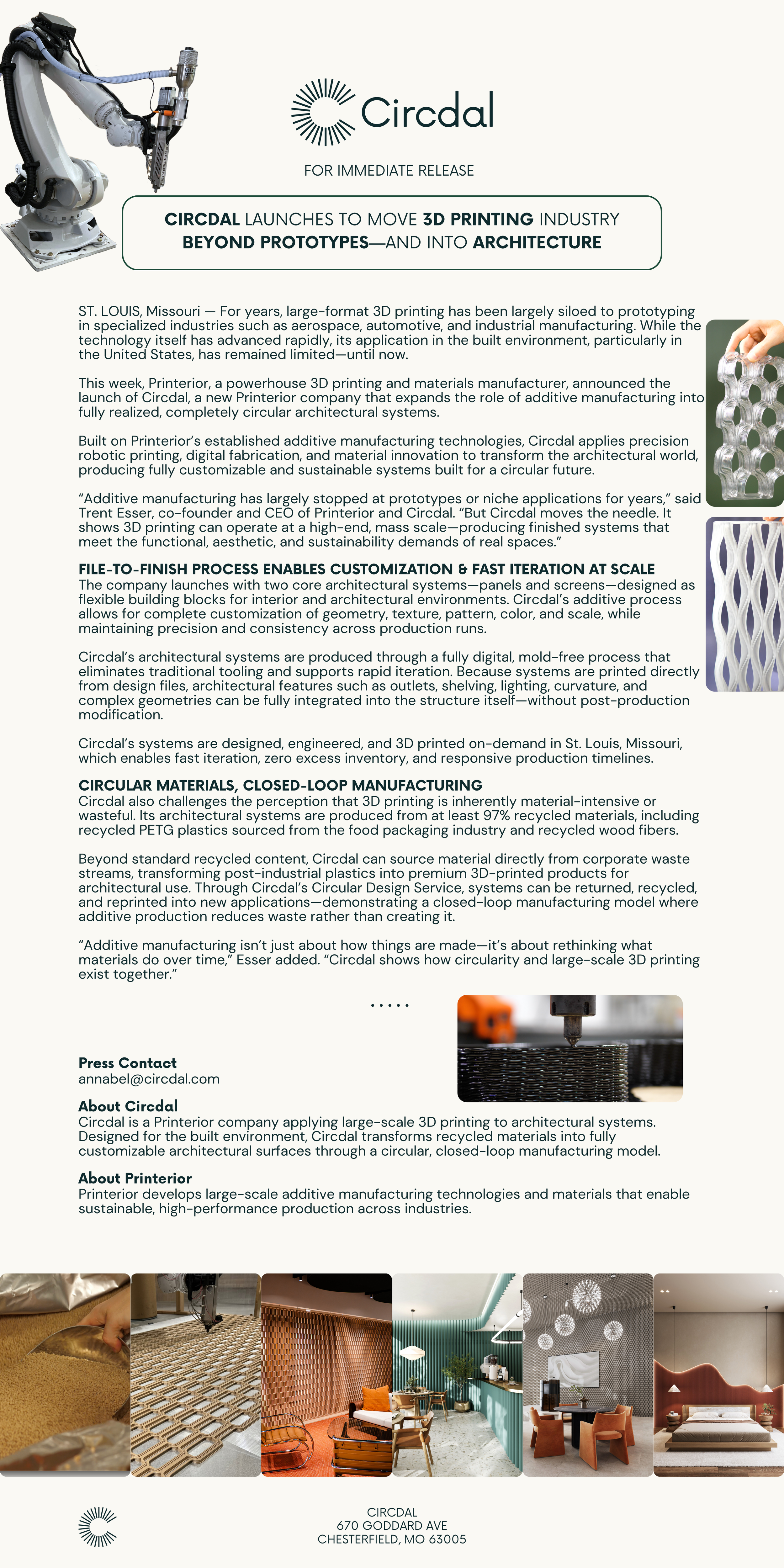

Built on Printerior’s established additive manufacturing technologies, Circdal applies precision robotic printing, digital fabrication, and material innovation to transform the architectural world, producing fully customizable and sustainable systems built for a circular future.

“Additive manufacturing has largely stopped at prototypes or niche applications for years,” said Trent Esser, co-founder and CEO of Printerior and Circdal. “But Circdal moves the needle. It shows 3D printing can operate at a high-end, mass scale—producing finished systems that meet the functional, aesthetic, and sustainability demands of real spaces.”

File-to-Finish Process Enables Customization & Fast Iteration at Scale

The company launches with two core architectural systems—panels and screens—designed as flexible building blocks for interior and architectural environments. Circdal’s additive process allows for complete customization of geometry, texture, pattern, color, and scale, while maintaining precision and consistency across production runs.

Circdal’s architectural systems are produced through a fully digital, mold-free process that eliminates traditional tooling and supports rapid iteration. Because systems are printed directly from design files, architectural features such as outlets, shelving, lighting, curvature, and complex geometries can be fully integrated into the structure itself—without post-production modification.

Circdal’s systems are designed, engineered, and 3D printed on demand in St. Louis, Missouri, which enables fast iteration, zero excess inventory, and responsive production timelines.

Circular Materials, Closed-Loop Manufacturing

Circdal also challenges the perception that 3D printing is inherently material-intensive or wasteful. Its architectural systems are produced from at least 97% recycled materials, including recycled PETG plastics sourced from the food packaging industry and recycled wood fibers.

Beyond standard recycled content, Circdal can source material directly from corporate waste streams, transforming post-industrial plastics into premium 3D-printed products for architectural use. Through Circdal’s Circular Design Service, systems can be returned, recycled, and reprinted into new applications—demonstrating a closed-loop manufacturing model where additive production reduces waste rather than creating it.

“Additive manufacturing isn’t just about how things are made—it’s about rethinking what materials do over time,” Esser added. “Circdal shows how circularity and large-scale 3D printing exist together.”

· · · · ·

Press Contact

annabel@circdal.com

About Circdal

Circdal is a Printerior company applying large-scale 3D printing to architectural systems. Designed for the built environment, Circdal transforms recycled materials into fully customizable architectural surfaces through a circular, closed-loop manufacturing model.

About Printerior

Printerior develops large-scale additive manufacturing technologies and materials that enable sustainable, high-performance production across industries.