St. Louis 3D Printing Company Launches Circdal, Redefining How Architecture Is Made

CONTACT · ANNABEL THORPE, CIRCDAL

PHONE · 214-543-8233

EMAIL · ANNABEL@CIRCDAL.COM

PRINTERIOR WEBSITE: printeriordesigns.com

Just need the text—no fluff? See below.

St. Louis 3D Printing Company Launches New Brand, Redefining How Architecture Is Made

ST. LOUIS, MO — A St. Louis company that began by pushing the boundaries of large-format 3D printing manufacturing is now taking on a new industry—architecture and design.

This week, Printerior, a St. Louis–based 3D printing and materials manufacturing company, announced the launch of Circdal, a new Printerior company focused exclusively on architectural systems made from at least 97% recycled material and built for a circular future. The launch marks Printerior’s first industry-specific expansion, transforming proprietary 3D printing technology designed, engineered, and printed in St. Louis into large-scale architectural systems shipped globally—proving St. Louis innovations can reshape environments worldwide.

“Printerior started as a manufacturing company focused on pushing what large-format 3D printing could do,” said Trent Esser, co-founder and CEO of Printerior and Circdal. “Circdal is an important next step—taking that same technology and applying it to architecture, where design freedom, scale, and sustainability really matter. It allows something developed in St. Louis to influence how spaces are designed and built far beyond our city.”

· Digital Manufacturing Technology to Architectural Systems ·

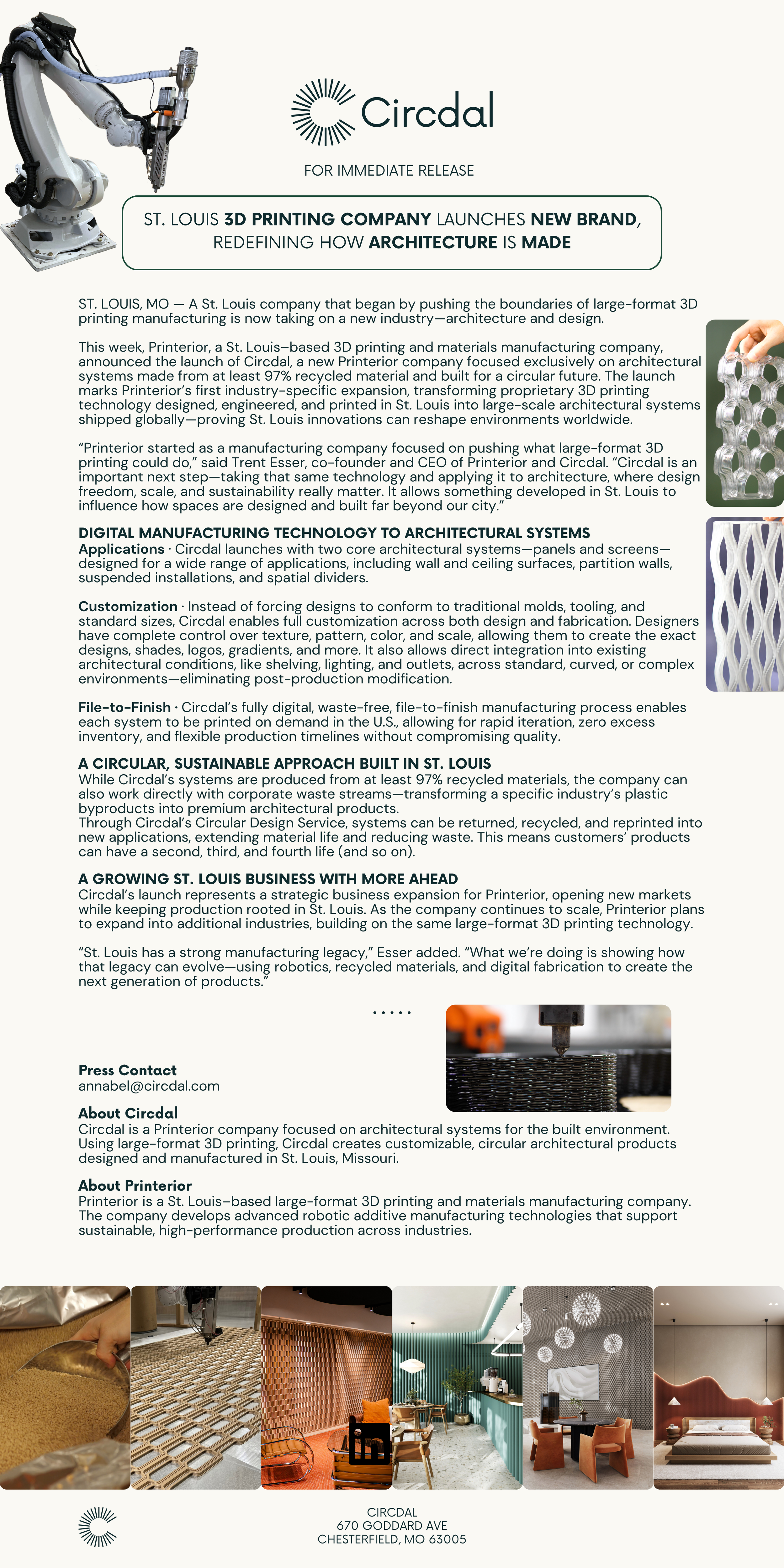

Applications · Circdal launches with two core architectural systems—panels and screens—designed for a wide range of applications, including wall and ceiling surfaces, partition walls, suspended installations, and spatial dividers.

Customization · Instead of forcing designs to conform to traditional molds, tooling, and standard sizes, Circdal enables full customization across both design and fabrication. Designers have complete control over texture, pattern, color, and scale, allowing them to create the exact designs, shades, logos, gradients, and more. It also allows direct integration into existing architectural conditions, like shelving, lighting, and outlets, across standard, curved, or complex environments—eliminating post-production modification.=

File-to-Finish · Circdal’s fully digital, waste-free, file-to-finish manufacturing process enables each system to be printed on demand in the U.S., allowing for rapid iteration, zero excess inventory, and flexible production timelines without compromising quality.

· A Circular, Sustainable Approach Built in St. Louis ·

While Circdal’s systems are produced from at least 97% recycled materials, the company can also work directly with corporate waste streams—transforming a specific industry’s plastic byproducts into premium architectural products.

Through Circdal’s Circular Design Service, systems can be returned, recycled, and reprinted into new applications, extending material life and reducing waste. This means customers’ products can have a second, third, and fourth life (and so on).

· A Growing St. Louis Business With More Ahead ·

Circdal’s launch represents a strategic business expansion for Printerior, opening new markets while keeping production rooted in St. Louis. As the company continues to scale, Printerior plans to expand into additional industries, building on the same large-format 3D printing technology.

“St. Louis has a strong manufacturing legacy,” Esser added. “What we’re doing is showing how that legacy can evolve—using robotics, recycled materials, and digital fabrication to create the next generation of products.”

· · · · ·

Press Contact

annabel@circdal.com

About Circdal

Circdal is a Printerior company focused on architectural systems for the built environment. Using large-format 3D printing, Circdal creates customizable, circular architectural products designed and manufactured in St. Louis, Missouri.

About Printerior

Printerior is a St. Louis–based large-format 3D printing and materials manufacturing company. The company develops advanced robotic additive manufacturing technologies that support sustainable, high-performance production across industries.